|

Eager Space | Videos | All Video Text | Support | Community | About |

|---|

The space shuttle first launched in April of 1981. (video) It was the world's first reusable launch system, with both the orbiter and the solid rocket boosters recovered and reflown and only the large external fuel tank thrown away.

Shuttle flew for 30 years, and during that time it remained the only operational system that recovered and reflew parts.

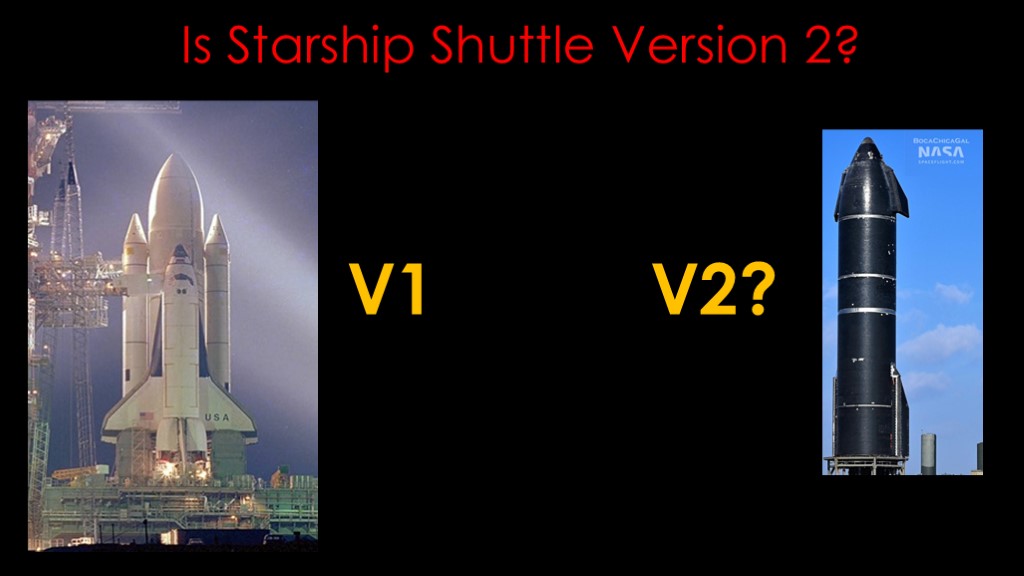

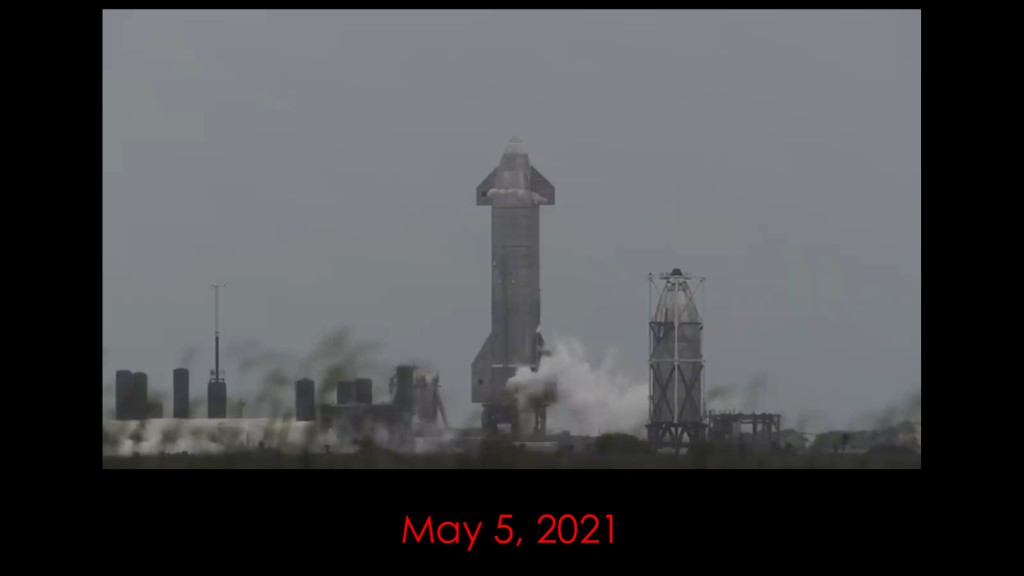

It's now 42 years later, and SpaceX is getting ready for the first flight of starship, which, if successful, will be the first fully reusable orbital launcher.

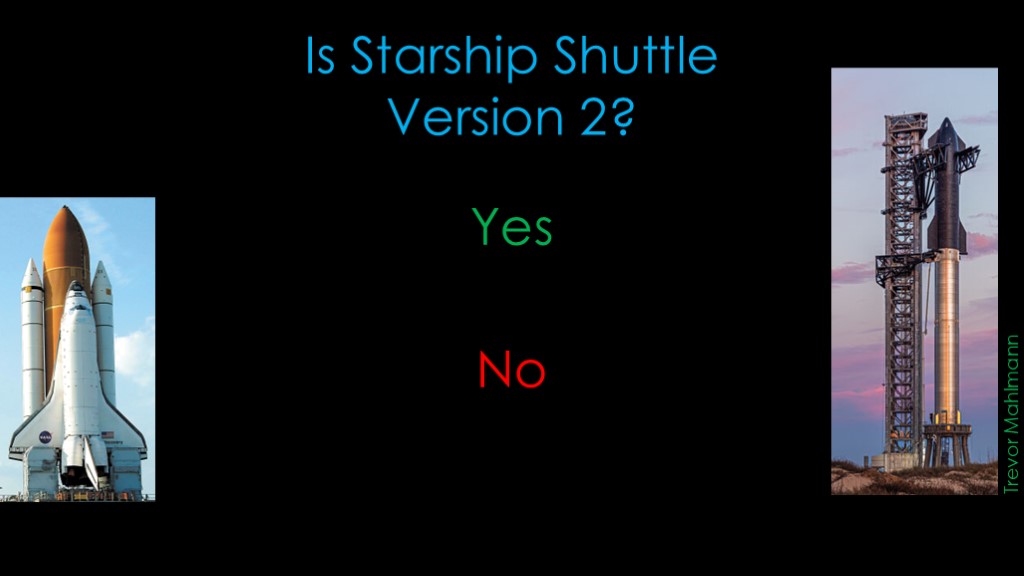

Is starship the follow-on to shuttle, the version 2 that NASA never built?

The space shuttle first launched in April of 1981. (video) It was the world's first reusable launch system, with both the orbiter and the solid rocket boosters recovered and reflown and only the large external fuel tank thrown away.

Shuttle flew for 30 years, and during that time it remained the only operational system that recovered and reflew parts. It was, however, never the cheap and reliable system that NASA had hoped for.

It's now 42 years later, and SpaceX is getting ready for the first flight of starship, which, if successful, will be the first fully reusable orbital launcher.

Is starship the follow-on to shuttle, the version 2 that NASA never built?

To answer this question, we'll need to figure out what NASA might want from shuttle 2.0.

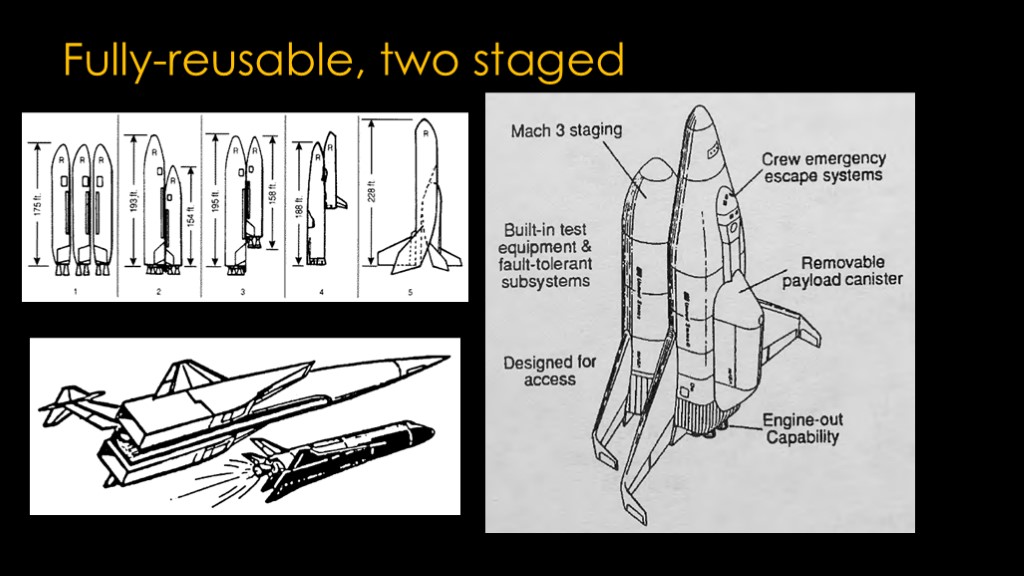

Based on these NASA proposals from before and after shuttle was developed, I'm going to assert that shuttle version two should be a fully-reusable, two staged vehicle.

We're going to focus on the second stage because that is the more challenging part of the design and that makes comparisons with shuttle easier.

Here's a nice video of the shuttle second stage in action.

The second stage is an orbiter that's about 37 meters long with 4.6 meter fuselage, and a much larger external fuel tank that measures 49 meters by 8.4 meters.

Here's the orbiter plus the external fuel tank.

To build a fully reusable version, we need to solve a significant packing problem.

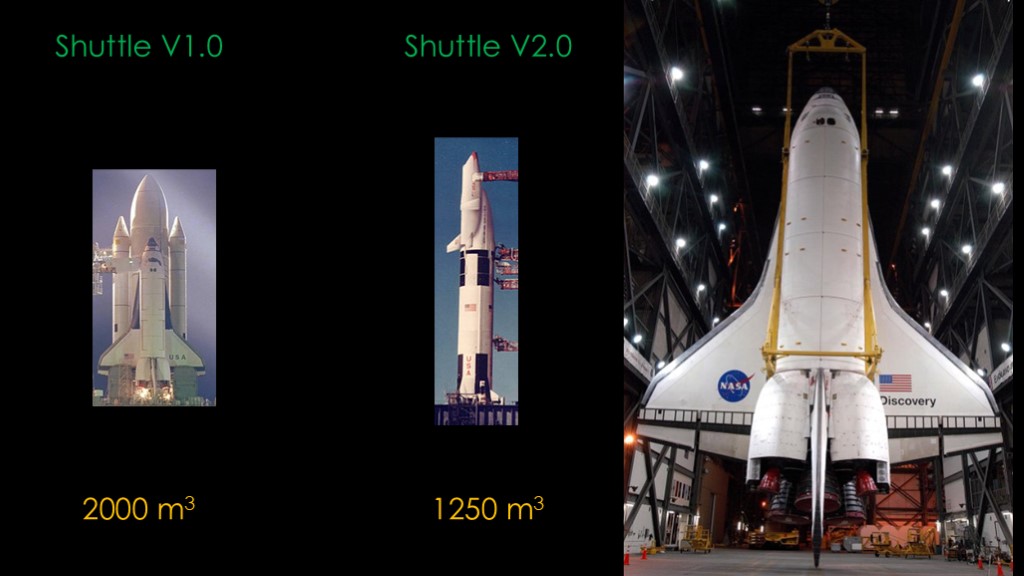

The expended external tank contains roughly 2000 cubic meters of propellant, and we will need to find a way to fit that propellant into the orbiter body.

The orbiter payload bay is about 300 cubic meters in volume, so this is a significant challenge. We will definitely need a bigger orbiter.

We can reduce that 2000 cubic meter requirement if we change our architecture.

The current shuttle is a "stage and a half" design - the orbiter engines ignite on the ground and run all the way to orbit. That requires quite a bit more fuel.

It also uses solid rocket boosters that aren't as beefy as a separate booster stage, so the upper stage needs to do more work.

If we get rid of the solid rockets and put a booster underneath the shuttle, we can cut down the requirements quite a bit, down to perhaps 1250 cubic meters.

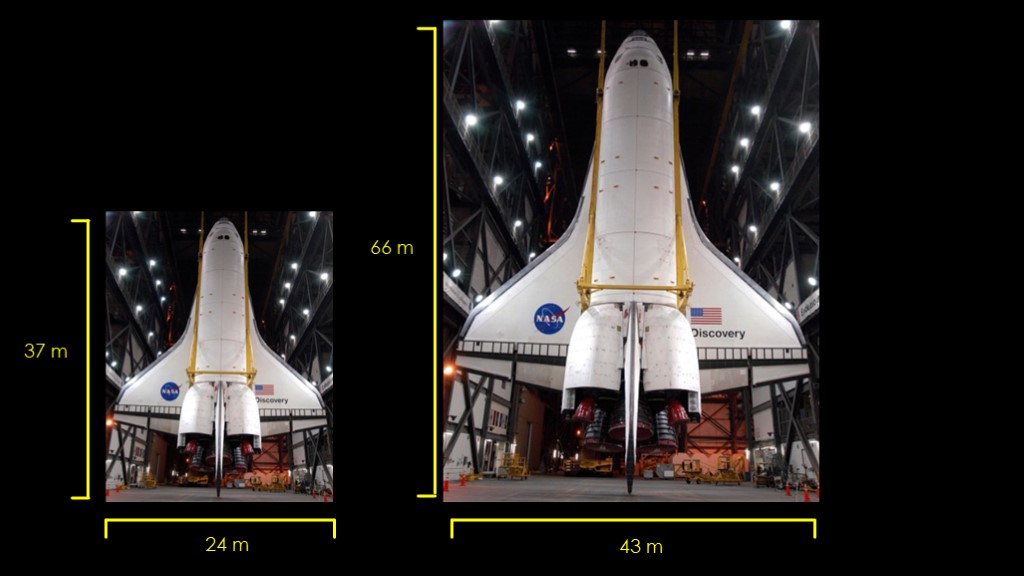

The v1 orbiter is 37 meters long and has a wingspan of 24 meters.

If we scale it up to hold all the propellant for our reusable version, we end up with truly huge 66 meter orbiter with a 43 meter wingspan.

That assumes that upsizing the orbiter only adds 26 tons of mass - the mass of the external tank. If the bigger orbiter gains more mass than that, it will need more fuel capacity and will end up even larger.

This bigger orbiter still has the same performance as the small one - it can lift about 27 tons to low earth orbit - but it would get rid of the expendable external tank.

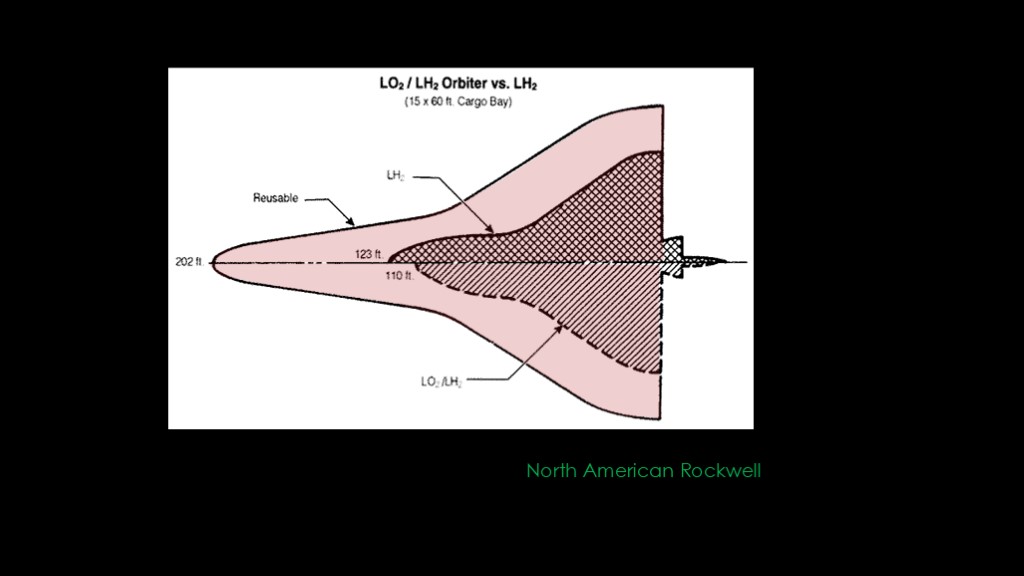

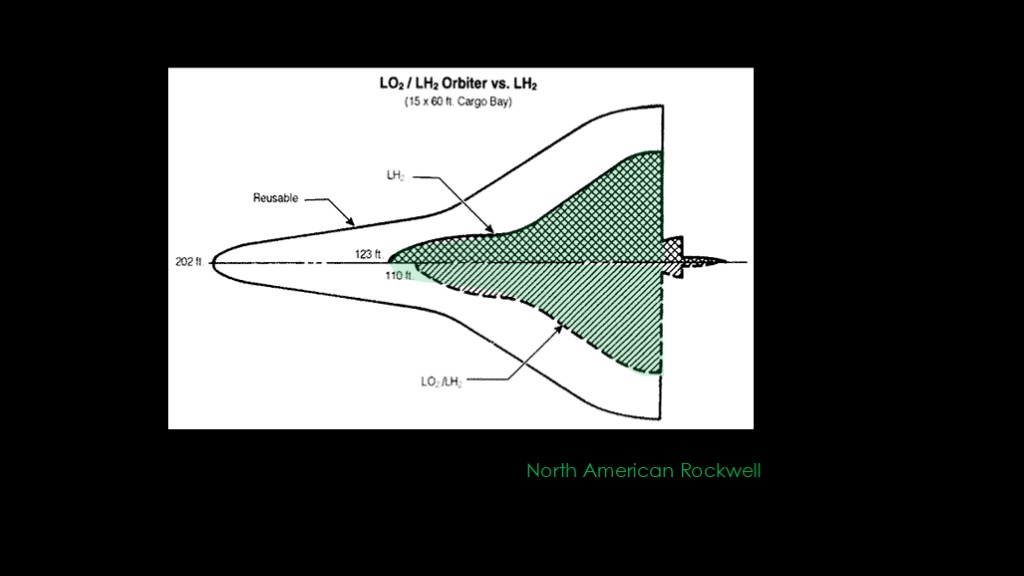

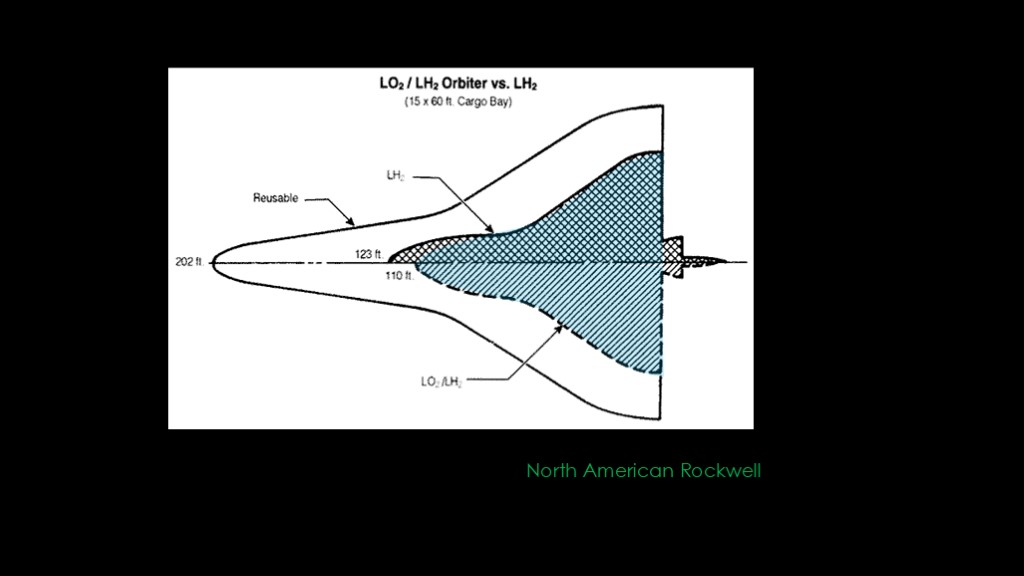

NASA had wrested with the size issue during the initial design of the orbiter. This is a drawing from North American Rockwell that shows that the shuttle would be 62 meters long if it carried all of its propellant internally.

It would be 37 meters if it carried the liquid hydrogen in an external tank.

And it would be 34 meters if both liquid hydrogen and liquid oxygen were carried in an external tank. Bigger means more expensive and more volume that you need to protect with heat shields.

NASA had a very limited budget, so they chose the external tank, giving up their dream of a fully reusable system.

For shuttle 2.0, it would be great if we could build a smaller orbiter than the mega shuttle

The problem is really one of propellant density.

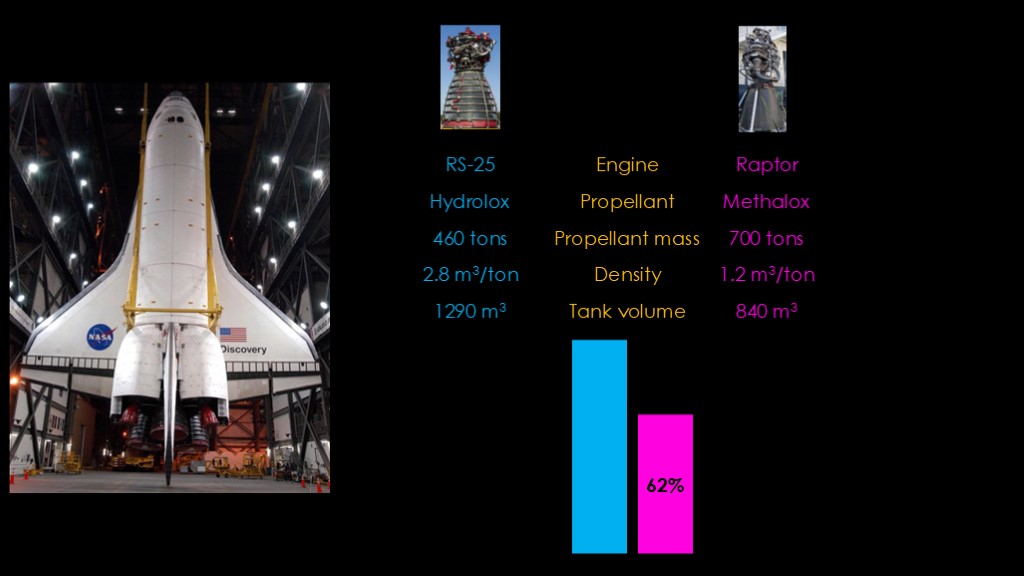

The space shuttle uses the RS-25, or space shuttle main engine. Its propellant is liquid hydrogen and oxygen, or hydrolox.

Our second stage variant carries 460 tons of propellant, and each ton of that propellant requires 2.8 cubic meters of tank volume, for a total of 1290 cubic meters of tankage. It takes a lot of space because liquid hydrogen is very low density.

What if we replaced the RS-25 with an engine that uses a different fuel?

SpaceX's Raptor engine burns liquid methane and oxygen, or methalox. This propellant combination is not as efficient as hydrolox, so it takes about 50% more fuel, or 700 tons total.

However, the liquid methane is much denser than the liquid hydrogen, so it only takes 1.2 cubic meters of tank to hold a ton of fuel, and a total of 840 cubic meters to hold 700 tons.

The result is that the required tank volume for the Raptor version is 38% less than the RS-25 version. That means a significantly smaller orbiter or, carrying more propellant for a larger payload.

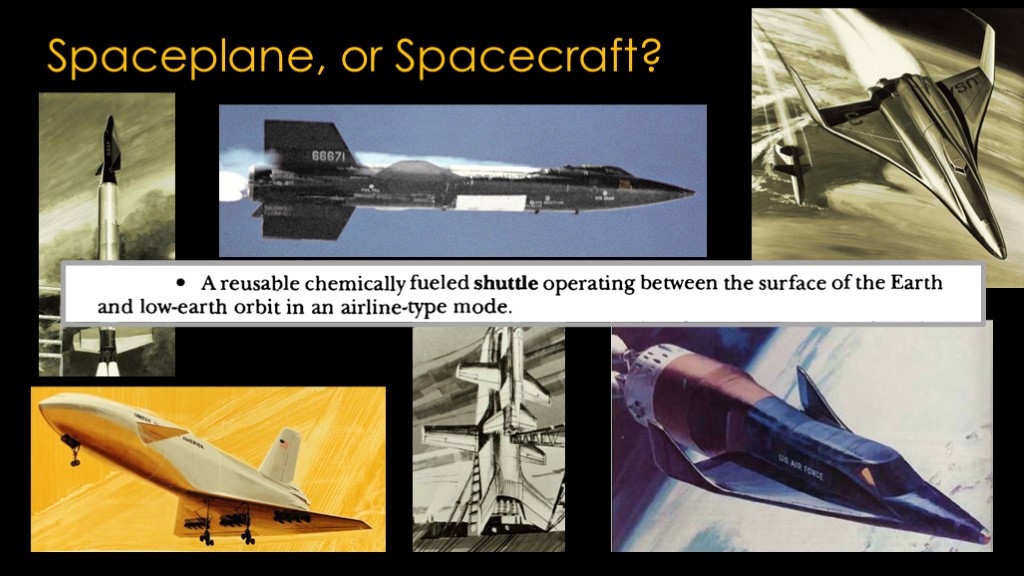

We will need to decide whether shuttle 2.0 should be a plane or something else?

The 1960s were a time of space planes, some real like the X-15, some proposed like the Dyna Soar, and many others as design concepts.

The language that started the shuttle program was pretty clear, specifying a chemically fueled shuttle operating between the surface of the earth and low-earth orbit in an airline-type mode.

It doesn't actually say that it would be a space *plane* - a craft that flies like a plane - but it was certainly implied, and from what I can tell all of the early shuttle designs were space planes and NASA never looked seriously at other options.

It turns out that there are a number of issues with the spaceplane design.

The shuttle required a very strong airframe that makes up the bottom half of the fuselage because the payload doors cannot carry any structural loads. That strong airframe is heavy.

It also required large and heavy wings and landing gear.

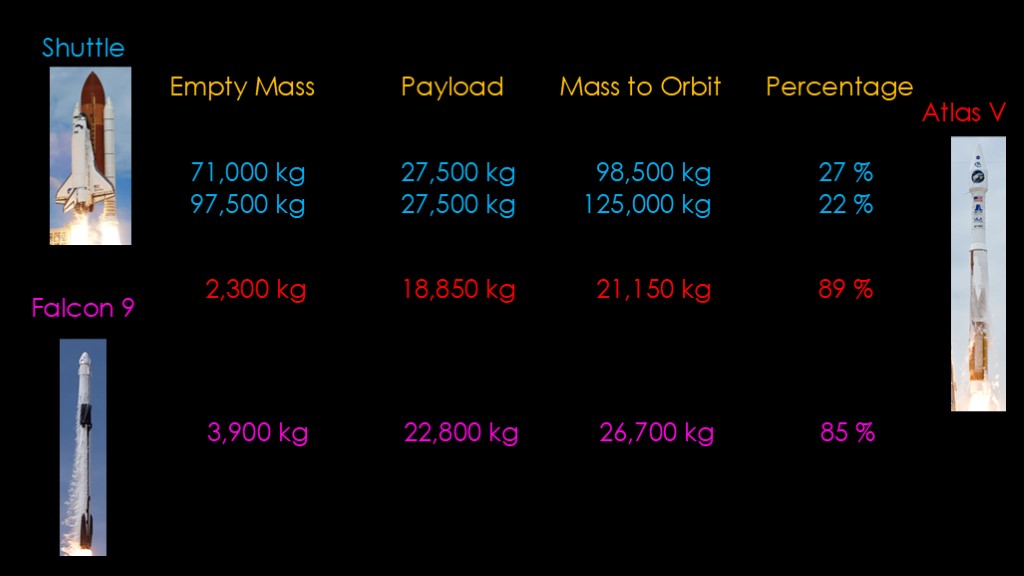

I'm going to make a few comparisons that are a bit unfair.

The shuttle has an empty of 71,000 kilograms, and its maximum payload to low earth orbit is 27,500 kilograms. That means that the total mass to orbit is 98,500 kilograms, and only 27% of the mass to orbit is payload.

If you want add in the external tank, the numbers go up by the mass of the external tank, and only 22% of the mass hauled to orbit is payload.

Looking at the Atlas V with its Centaur second stage, we see that the empty second stage is a very light 2300 kilograms and carries a payload of 18,850 kilograms, giving a payload percentage of 89%.

The Falcon 9 second stage has a mass of 3900 kilograms and a payload of 22,800 kilograms, for a payload percentage of 85%.

As I noted, this is an unfair comparison because neither the Atlas V nor Falcon 9 have reusable second stages, but it does illustrate one of the reasons shuttle v1 was so big and so expensive - it carried nearly 125,000 kilograms of mass to orbit and only about 27,000 kilograms was payload.

The point is that the shuttle architecture was reusable but it wasn't very efficient, and one of the reasons is the big and heavy orbiter.

Cost is also an important factor.

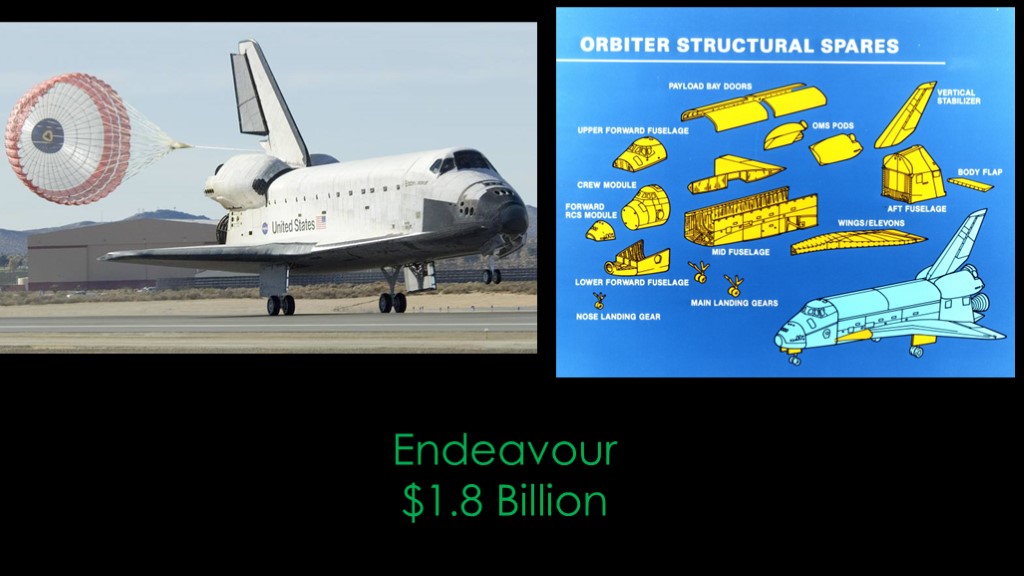

When space shuttle Endeavour was built in 1987 to replace Challenger, it cost $1.8 billion, and it was only that cheap because there were a large number of structural spares leftover from the construction of the original orbiters. Our bigger fully reusable orbiter would obviously cost more.

This is one answer to "why isn't there a shuttle 2.0?" If you are looking at vehicles that are a few billion dollars each, your development project is going to be very expensive, and with NASA spending their money flying shuttle there was no money to create a replacement.

Is there an alternative?

A way to build a vehicle that is fully reusable, more efficient, and cheaper to build and operate?

If we look back at vintage science fiction, we find a large number of spacecraft that are tail-landers, for the very simple reason that spaceplanes require both atmosphere and runways.

And, of course, one of NASA's most famous spacecraft was a tail lander...

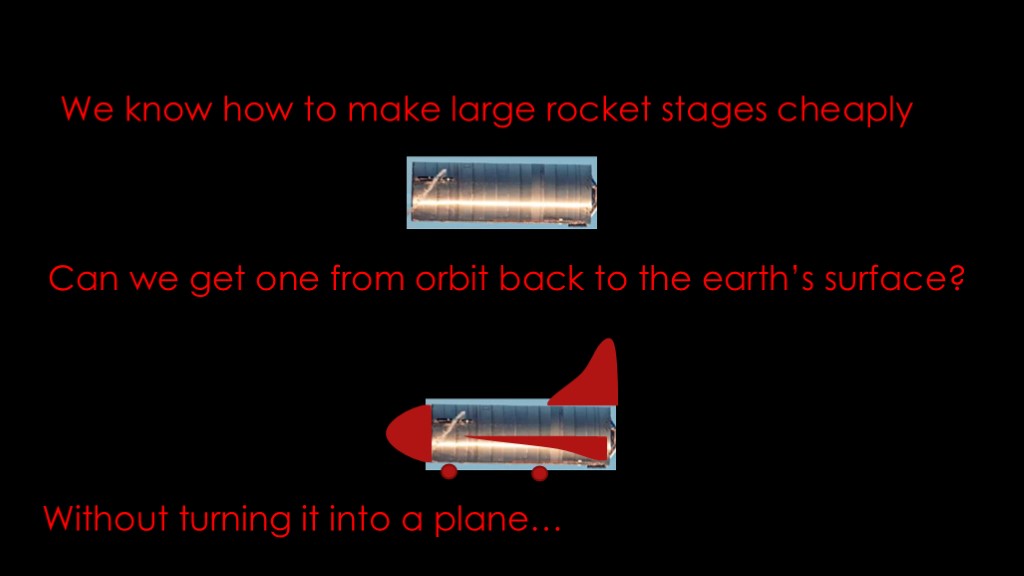

Those second stages I was talking about earlier look interesting. We know how to make large rocket stages cheaply.

Can we get one from orbit back to the earth's surface?

Without adding the disadvantages of turning it into a plane.

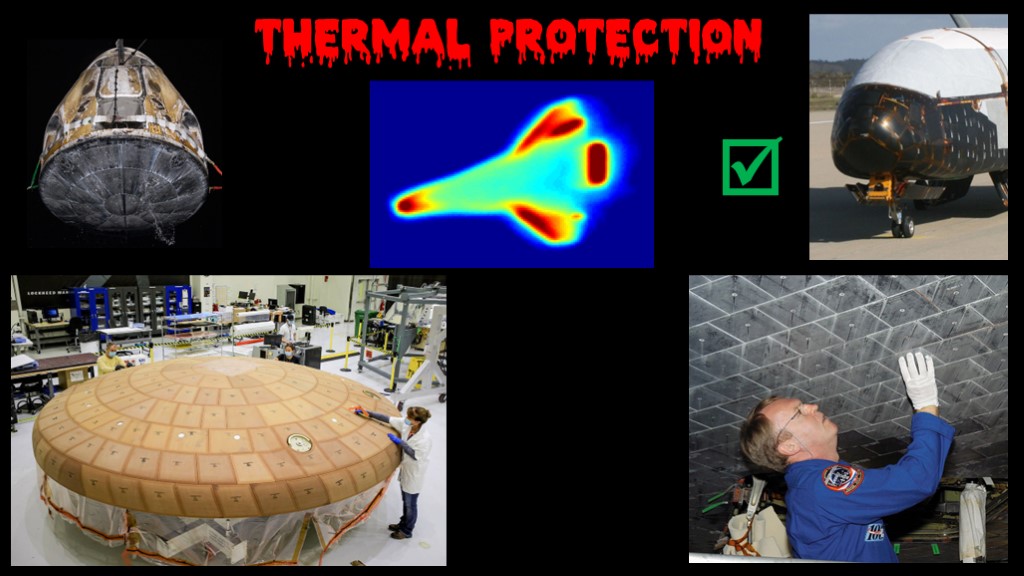

The first challenge with any reentry vehicle is thermal protection - a way to deal with the heat of reentry.

There are two traditional approaches to deal with this.

The first is the ablative heat shield used on capsules like Dragon and Orion - it has a material that slowly chars and vaporizes to deal with the heat.

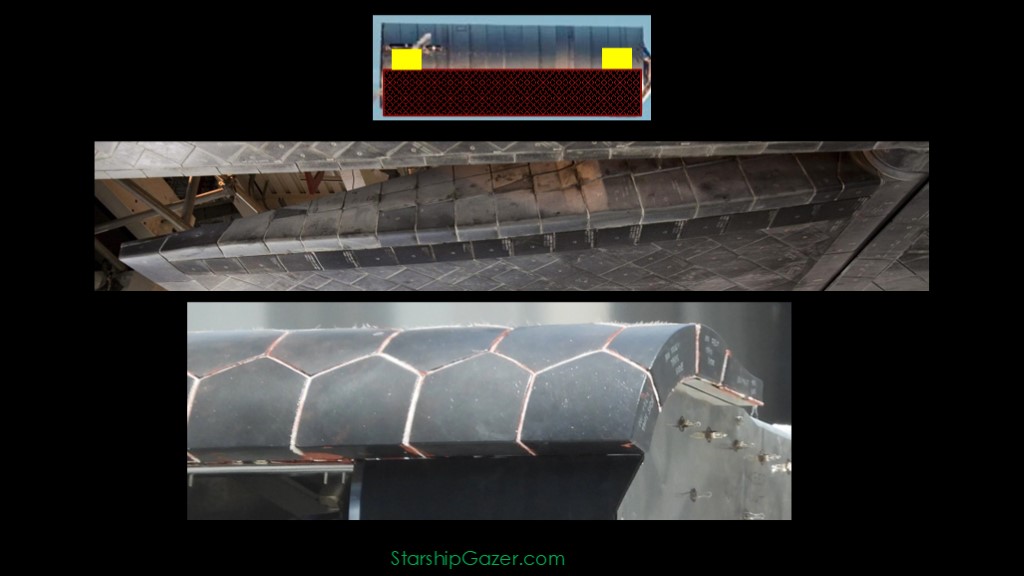

And the second is a tiled approach used on the shuttle and vehicles like the X-37. This thermal protection can be reused but may need maintenance between flights.

Since we want to be easily reusable, some sort of tile-based approach makes more sense.

We will therefore need to cover the bottom of our second stage with heat shield tiles.

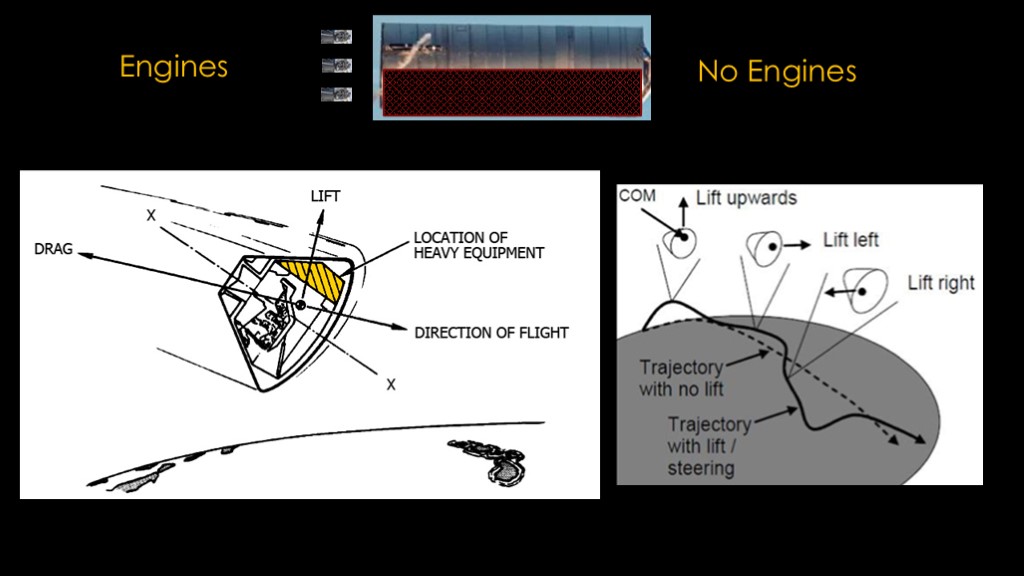

Our second challenge is to control our vehicle orientation and flight path. If the heat shield ends up facing upwards, this might happen.

Capsules do this with a neat trick...

Their center of mass is designed so that the capsule is stable with the heat shield pointing in the right direction, and it is also offset to one side by placing heavier equipment on that side. That tilts the heat shield to the side and generates lift.

That lift can then be used to control the path of the capsule by rotating the capsule around with its thrusters.

Unfortunately, we have two problems. The first is that our vehicle is mostly symmetrical in mass distribution, so there's not a lot of natural forces keeping the heat shield on the bottom.

The second problem is that we have a lot of heavy engines and structure at the bottom of our second stage, and no engines at the top, so our center of gravity is doing to be mostly near one end.

Which means we can't use the low tech "capsule" approach, and instead we need an approach with active control surfaces, like the shuttle, but not a plane.

We can do this fairly simply.

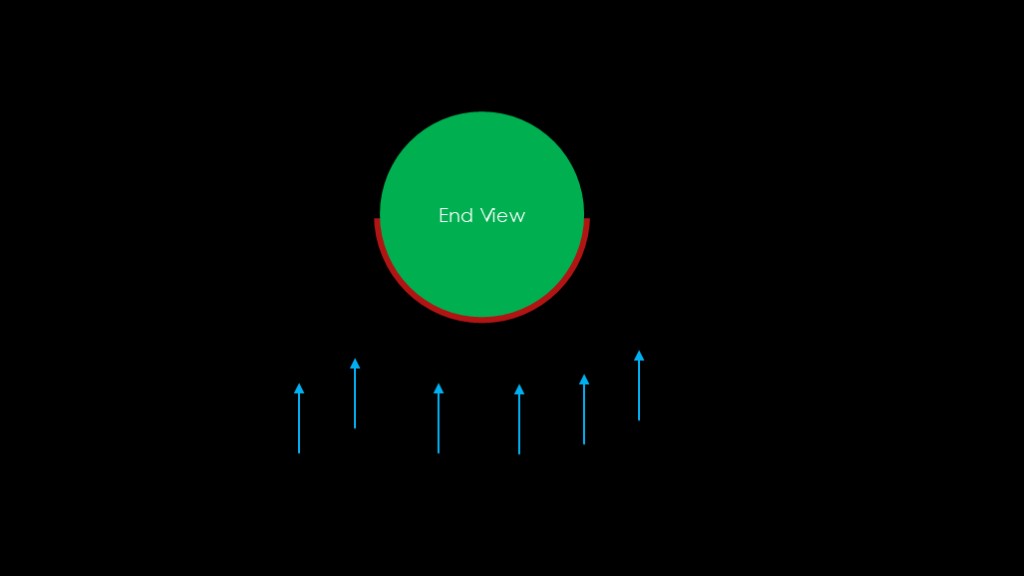

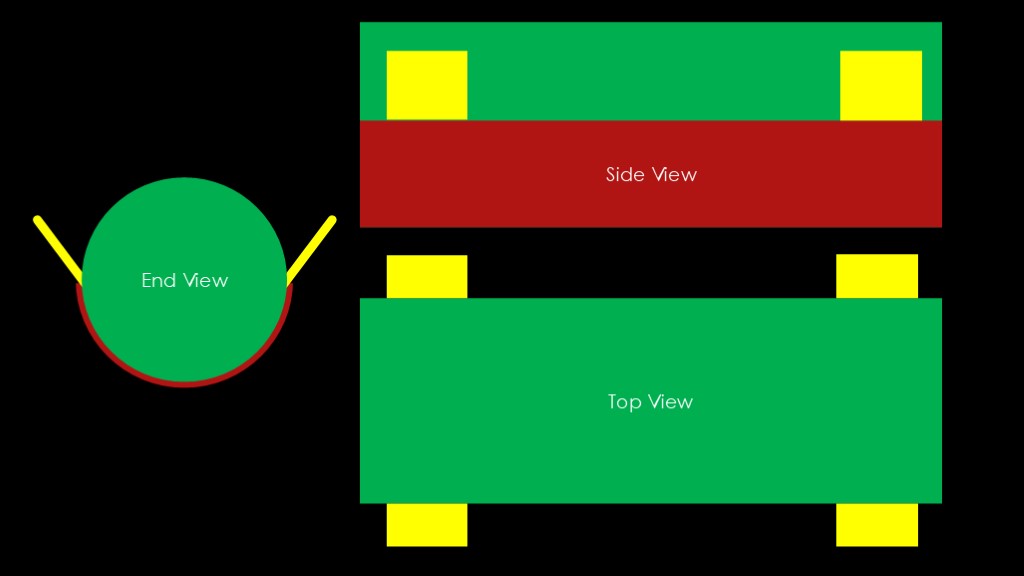

Our vehicle is a long cylinder with heat shield on the bottom, and the air is rushing past it.

We need a way to keep the heat shield on the bottom.

If we add fins to the sides, we can move them from one side to the other.

Push them one direction, and it will cause a rotation in one direction. Push then the other way, it will cause a rotation in the opposite direction.

That's what we need to keep the heat shield facing our direction of travel.

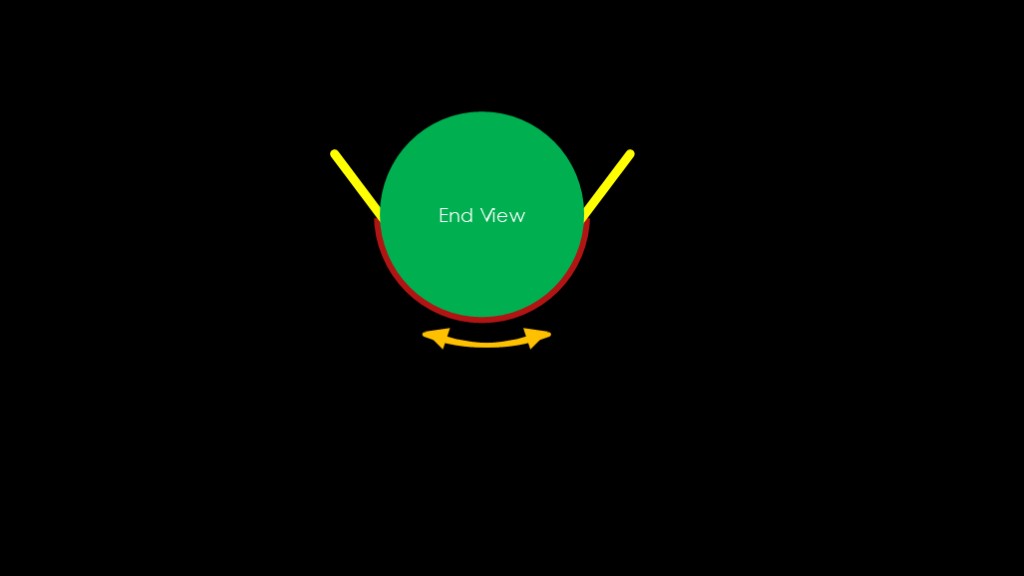

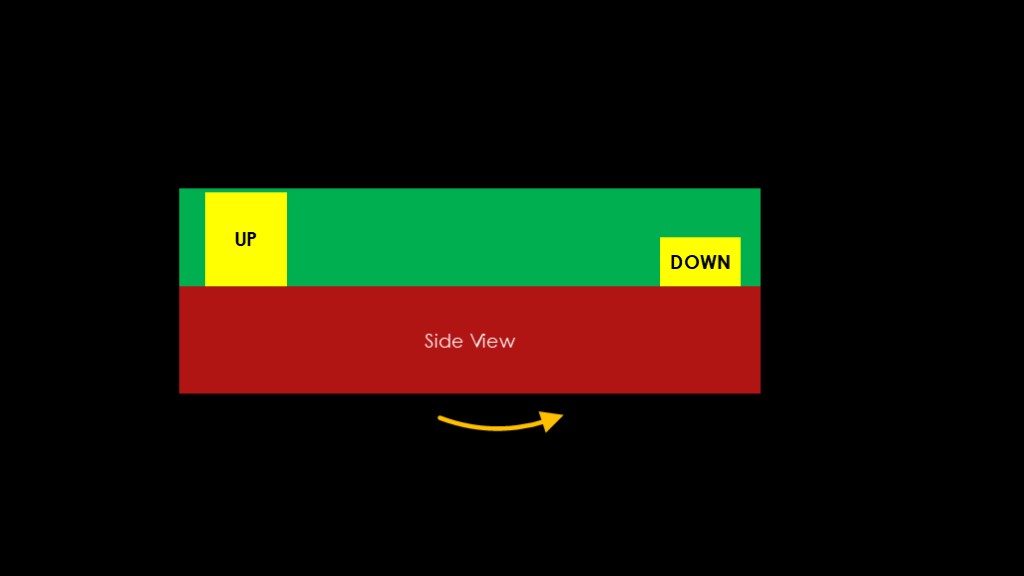

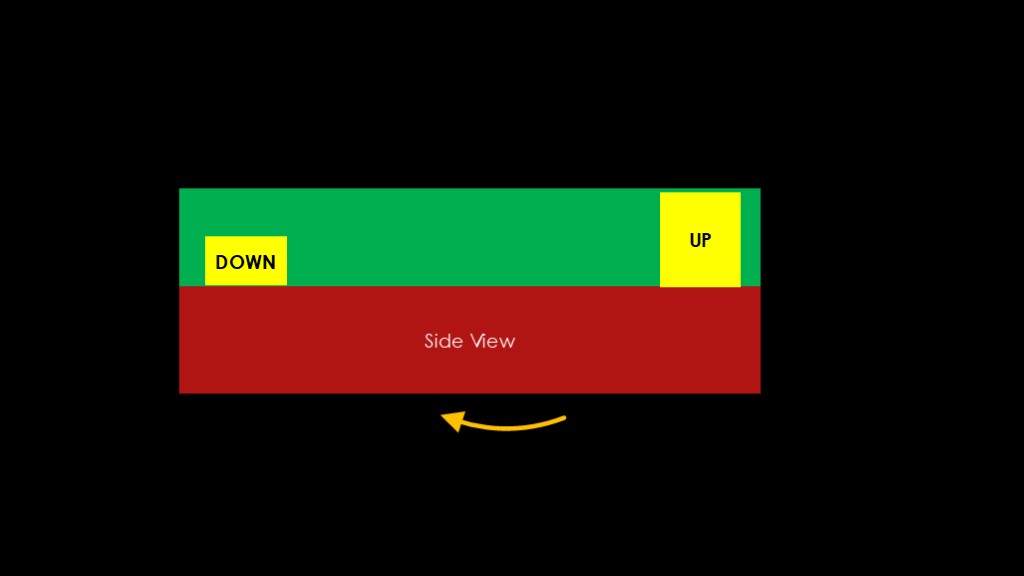

Looking from the side, if the fins at the left are up and the ones at the right are down, there is more drag on the right, and that rotates one direction.

Flip them the other way, and we get the opposite rotation.

That's two degrees of control.

And finally, looking from the top, with this arrangement, we rotate to the right

And this arrangement rotates to the left.

The fins give us the ability to control the vehicle during reentry.

These fins do, of course, make our heat shield harder - we need to deal with more complex curves, but that's a solvable problem. We'll just need to get more complex with our tile shape.

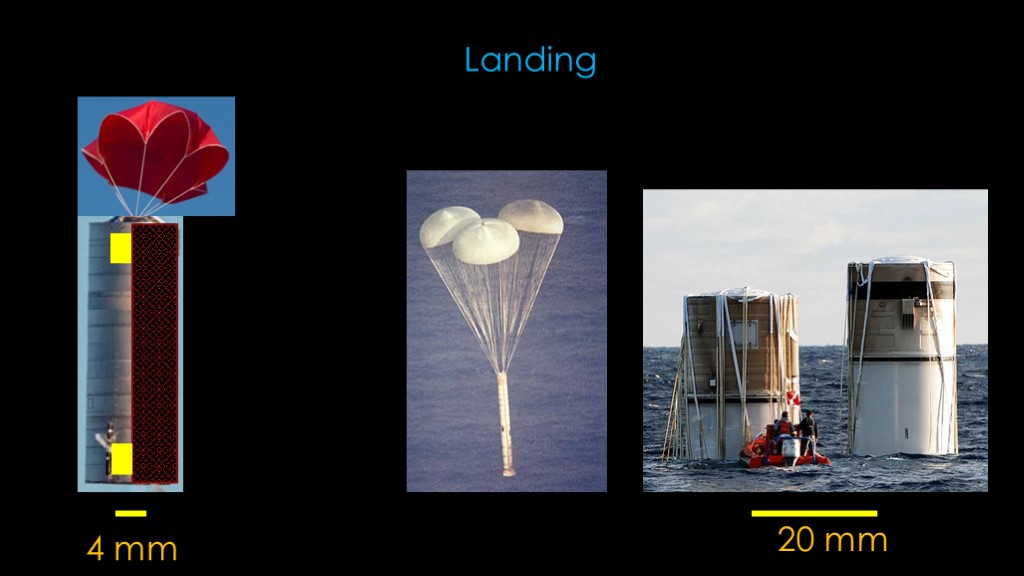

And now we need to move onto landing. The first question to ask is "can we use a parachute?"

The solid rocket boosters from the shuttle program weighed about 90 tons, so roughly what our second stage might weigh, and they were parachuted down and landed in the water. They were towed to port, disassembled, and then shipped off to the factory to be reused.

The SRBs used for shuttle had 20 millimeter thick steel walls. Liquid fueled stages are much thinner, with walls around 4 millimeters thick, or even thinner. That makes it harder to survive the force of landing.

And remember that our stage has heavy and expensive engines that don't react well to being dipped in salt water, while solid rocket boosters are mostly just big empty tubes.

Regardless, even if this did work, parachutes aren't very controllable.

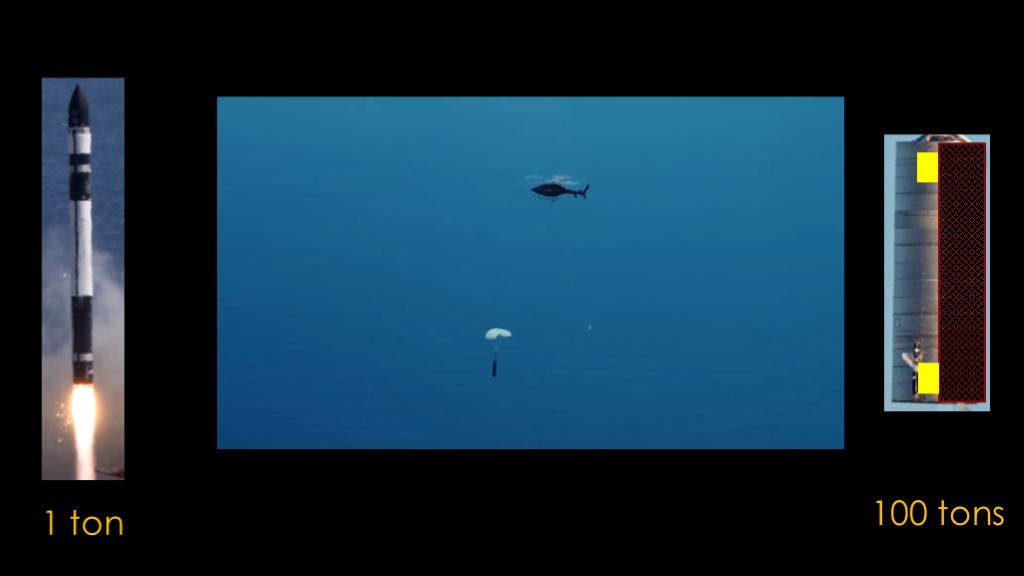

At this point, somebody is probably saying "what about electron?"

Electron is working towards recovering their booster with a helicopter, as shown in this test flight.

Unfortunately for this approach, the electron booster weighs about 1 ton, and the stage we want to do this with might be up to 100 tons. There are no helicopters that can lift that much weight.

So we're going to use the fins to guide us and then, as we near the ground, use thrusters and rockets to spin back to vertical and land.

Which leads us to a vehicle like this...

Which brings us back to our original question. Is starship shuttle version 2?

The answer is "Yes", in the sense that it will, if successful, do the things that shuttle could do, but do them better.

The answer is "No", as it uses a different architecture than shuttle and is wildly more ambitious in its goals than shuttle

If you enjoyed this video, please listen to track one of "Freedom at point zero".